Rational design of polymer networks

Soft materials, including hydrogels, elastomers, liquid crystals, granular materials, and foams, are suitable for biocompatible or bioinspired applications owing to their viscoelastic properties. For example, hydrogels can be engineered with properties that are similar to biological tissues,, including with tunable stiffness, high water content, and hierarchical structure. Viscoelastic and stimulus-responsive polymer networks can be applied for additive manufacturing or 3D printing, for sensing, and for drug delivery. In order to design soft materials with desired properties, we need improved understanding of how the (macro)molecular structure of the material controls the resulting macroscopic properties. A central focus of our laboratory is to synthesize and characterize a range of polymer networks to provide engineering design criteria for this class of materials.

Material design

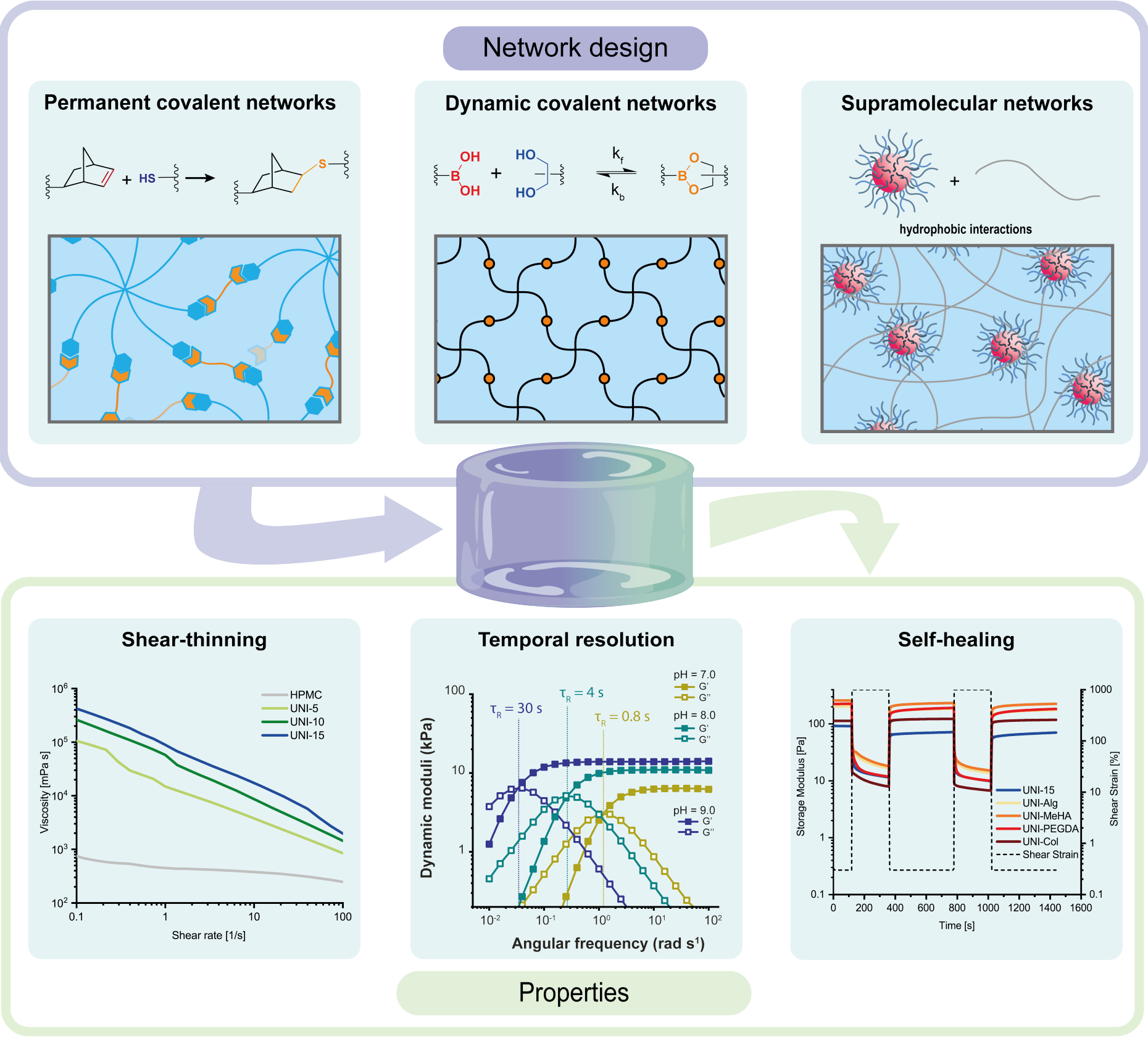

The (macro)molcular design of a polymer network influences the properties (e.g., mechanics/rheology, stimuli responsiveness, biocompatibility) of the final material. Engineering the network topology and molecular interactions between constitutive components enable precise tuning of the emergent macroscale properties. This can be achieved using polymers with different architectures such as linear, branched, or star polymers. Our laboratory is particularly interested in describing how network architecture in close to ideal systems—such as polymer networks based on star PEG—or more complex materials—such as nanocomposite networks based on interactions between nanoparticles and polymers—defines material properties.1,2

Another key focus is on the specific chemistries or interactions used to cross-link the system. Depending on the type of chemistry used—permanent covalent, dynamic covalent, or supramolecular—the material can be designed with a range of useful properties. Our group is currently investigating multiple self-assembling interactions for the design of moldable, printable, and injectable hydrogels with a specific focus on supramolecular and dynamic covalent chemistries as well as peptide self-assembly.2, 3

As biological applications are one of the main focus of our laboratory we also aim at designing networks not only from synthetic polymers but also from natural materials such as peptides, proteins, or naturally-derived polymers.

People involved: Elia Guzzi, Stéphane Bernhard, Lucien Cousin, Dalia Dranseikiene, Morris Wolf, Nika Petelinsek and Dr. Stefan Mommer.

Selected publications:

[1] Appel, Tibbitt et al., Nat. Commun. 2015, 6, 6295.

[2] Marco-Dufort et al., J. Am. Chem. Soc. 2020, 142, 15381.

[3] Bernhard et al., Adv. Drug Deliv. Rev. 2021, 171, 240.

[4] Bovone et al., ACS Biomaterials. Sci. Eng. 2021, 7, 4048.

Materials characterization

In order to connect material design to material properties, we perform extensive rheological analyses of the soft materials we prepare in the lab. Oscillatory rheology enables the investigation of viscoelastic behavior of a material under shear, enabling quantitative description of its properties such as dynamics, shear-thinning, self-healing, and relaxation behavior.1 Our group uses rheology for the investigation of the properties of designed materials but also as a tool to relate the observed properties to the molecular properties of the network.2

People involved: Elia Guzzi, Stéphane Bernhard, Lucien Cousin, Jonas Binz, Nika Petelinsek and Dr. Stefan Mommer.

Selected publications:

[1] Tibbitt et al., Macromolecules 2013, 46, 2785.

[2] Marco-Dufort et al., J. Am. Chem. Soc. 2020, 142, 15381.